Exploring Trenchless Technology

- Camjet Pty Ltd

- Sep 13, 2024

- 2 min read

Updated: Sep 26, 2025

In the evolving landscape of infrastructure maintenance, trenchless technology is emerging as a game-changer, particularly in pipeline rehabilitation. Traditional pipeline repair methods, which often involve extensive excavation, are not only disruptive but also time-consuming and costly. In contrast, trenchless methods like Camjet's Cured in Place Pipe (CIPP) repair offer a revolutionary approach.

Firstly What is CIPP?

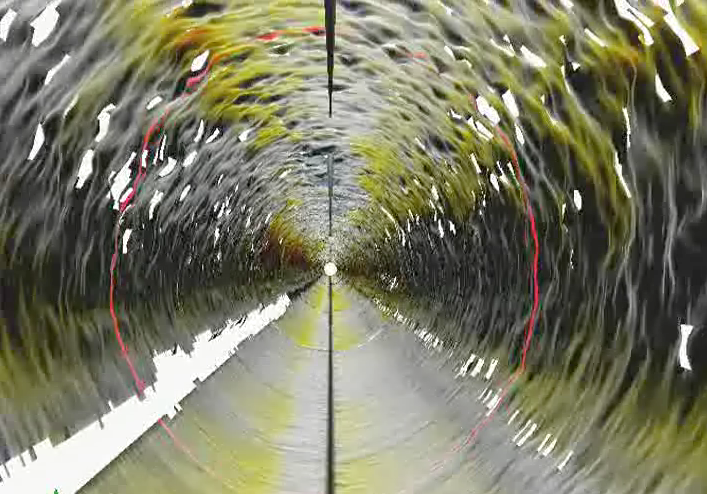

CIPP means Cured-in-Place-Pipe Lining (CIPP) is a trenchless method of sewer construction. It requires little or no digging and significantly less time to complete than other sewer repair methods. It is suitable for repairing both short and long runs of pipes that do not need to be upsized.

CIPP is a trenchless rehabilitation method used to repair existing pipelines. Instead of digging up and replacing damaged pipes, CIPP involves inserting a flexible liner saturated with resin into the existing pipe. This liner is then inflated and cured in place, forming a new, durable pipe within the old one. The process is versatile and can be used for various pipe materials, including clay, concrete, and PVC, making it suitable for diverse applications in municipal, industrial, and residential settings.

Advantages of CIPP and Trenchless Technology

Efficiency

One of the standout benefits of CIPP is its efficiency. Traditional methods require digging trenches, which can take days or even weeks. CIPP, on the other hand, can often be completed within hours, significantly reducing downtime. This rapid turnaround is particularly beneficial for critical infrastructure where prolonged disruptions are not an option.

Environmental Benefits

CIPP is also a more environmentally friendly option. By avoiding the need for excavation, it minimizes soil displacement and the associated environmental impacts. Additionally, the process uses fewer resources, as the existing pipe is essentially recycled by becoming the host for the new liner. This approach reduces the carbon footprint of the repair process and aligns with sustainable practices.

Minimal Disruption

The non-invasive nature of CIPP means that surface-level disruptions are minimal. There's no need to tear up roads, sidewalks, or landscaping, which not only preserves the environment but also reduces the social and economic impact on communities. Traffic, business operations, and daily life can continue with little to no interruption, making CIPP an ideal choice for urban and suburban areas.

As infrastructure continues to age, the need for effective, sustainable, and minimally disruptive pipeline rehabilitation solutions will only grow. Camjet's CIPP repair method is at the forefront of this evolution, offering a glimpse into the future of pipeline maintenance. By choosing CIPP, municipalities, industries, and homeowners can ensure that their pipelines are restored quickly, efficiently, and with minimal impact on the environment and the surrounding community.

Comments