Exploring Laser Profilers: Enhancing Submerged Pipe Inspection with Precision

- Camjet Pty Ltd

- Aug 27, 2024

- 2 min read

Updated: May 21, 2025

In the realm of infrastructure maintenance and inspection, the importance of thorough assessments cannot be overstated. Among the various tools and technologies employed for this purpose, laser profilers stand out as a revolutionary solution, especially when it comes to examining submerged or semi-submerged pipes.

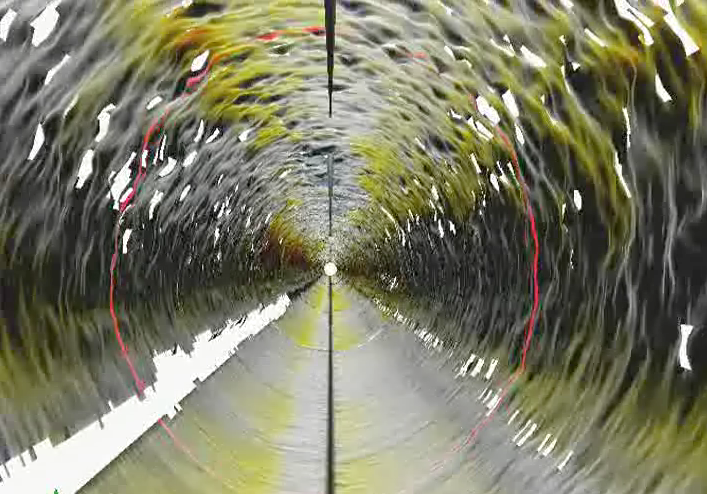

Offering a detailed two-dimensional profile of the interior pipe wall, including dimensional data of significant items or defects, laser profilers are transforming the way we approach pipeline inspection and maintenance.

Understanding Laser Profilers

Laser profilers are sophisticated devices designed to capture high-resolution data of pipe interiors with remarkable precision. These devices utilize laser technology to scan the inner surfaces of pipes, creating accurate profiles that offer invaluable insights into the condition of the infrastructure. Whether it's for assessing corrosion, detecting defects, or measuring dimensional data, laser profilers provide a comprehensive view of the pipe's interior, enabling engineers and inspectors to make informed decisions regarding maintenance and repairs.

Application in Submerged Environments

One of the most significant advantages of laser profilers is their ability to operate effectively in submerged or semi-submerged conditions. Traditional inspection methods often struggle to provide accurate data in such environments due to visibility issues and the challenges associated with accessing submerged pipes. However, laser profilers overcome these limitations by utilizing advanced laser scanning technology that can penetrate water and capture detailed profiles of the pipe interior with remarkable clarity.

Benefits of Laser Profilers for Submerged Pipe Inspection

Precision Measurement

Laser profilers offer unparalleled precision when it comes to measuring the dimensions of pipes and identifying defects. From wall thickness variations to the detection of cracks or deformities, laser profilers provide highly accurate data that allows inspectors to assess the integrity of the pipeline with confidence.

Enhanced Efficiency

By automating the inspection process and providing real-time data analysis, laser profilers significantly enhance the efficiency of pipeline inspections. This not only reduces the time and resources required for assessment but also minimizes downtime for critical infrastructure.

Improved Safety

Inspecting submerged pipes can be hazardous, particularly in challenging environments such as wastewater systems or offshore installations. Laser profilers help mitigate these risks by enabling remote inspection capabilities, reducing the need for human intervention in potentially dangerous settings.

Comprehensive Reporting

Integration with software solutions like WinCan V8 allows for the generation of comprehensive inspection reports based on the data collected by laser profilers. These reports provide detailed insights into the condition of the pipeline, facilitating informed decision-making and prioritization of maintenance activities.

Future Outlook

As technology continues to evolve, the capabilities of laser profilers are expected to further improve, ushering in a new era of pipeline inspection and maintenance. From advancements in data analytics to the development of more compact and versatile profiling devices, the future of submerged pipe inspection looks promising with laser profiling technology at its forefront.

Laser profilers represent a significant advancement in the field of pipeline inspection, particularly in submerged or semi-submerged environments. By offering precise measurements, enhanced efficiency, improved safety, and comprehensive reporting capabilities, laser profilers empower engineers and inspectors to effectively assess the condition of critical infrastructure and ensure its continued reliability. As we embrace these innovative technologies, we move closer to a future where pipeline maintenance is not only more effective but also more sustainable and resilient.

Comments